Natural gas plumbing is the backbone of many commercial and industrial operations. These systems deliver fuel for heating, cooking, water heating, and various processes. Proper piping is essential, not just for performance and durability, but also for safety and regulatory compliance. For reliable pipe selection and installation, you should hire a gas plumber with years of experience and proven skills in this field.

When installing new gas appliances or upgrading to energy-efficient systems, it is essential to evaluate existing gas lines for safety and compatibility. Galvanized steel gas pipes, once common, are now discouraged due to corrosion risks that can lead to gas leaks and poor air quality.

For indoor gas piping, stainless steel gas pipes, black iron, or copper tubing (in some propane gas applications) are safer alternatives. Steel piping typically serves as the standard for the main gas line, but your gas company may recommend replacing outdated galvanized steel pipes to meet modern safety standards across various types of gas systems, including natural gas pipes.

Steel Pipes

Benefits

- Strength and durability: Black steel pipes withstand high pressure and are resistant to impact and crushing, which is ideal for underground or exposed runs.

- Widely accepted: Many energy codes assume steel as the default gas pipe, making permitting and inspections smoother.

- A stainless steel pipe is cost-effective for long runs, especially in large commercial facilities with extensive underground networks.

Drawbacks

- Heavier and harder to maneuver, requiring threading and fitting or welding.

- Susceptible to corrosion if not properly coated or maintained, particularly underground or in damp environments.

- More labor-intensive, needing pipe threads, cutting tools, and penetrating oil during installation.

Plastic Pipes (HDPE, PVC)

HDPE (High-Density Polyethylene)

- Flexible and corrosion-resistant: Excellent for underground applications and trenchless installations.

- Lightweight and easy to install, often with heat fusion joints that eliminate leak-prone fittings.

PVC

- Generally not approved for natural gas in most jurisdictions—reserved for mechanical or water services.

- Where allowed, typically limited to low-pressure, non-critical situations.

Limitations

- UV and chemical sensitivity: Requires protective burial in sunlight-exposed areas.

- Installation training needed: Quality of fusion joints is critical—bad connections lead to leaks.

Copper Pipes

While common in residential water lines, copper is rarely used for gas in commercial settings due to:

- Price and theft risk, making it less practical for outdoor or exposed pipework.

- Chemical sensitivity: Some gases may degrade copper over time under pressure.

- Code restrictions: Many local ordinances prohibit copper for natural gas, particularly underground.

CSST (Corrugated Stainless Steel Tubing)

What is CSST?

Flexible, lightweight tubing corrugated to allow easy bends and routing. It comes in elemental-resistant versions that permit bonding to the electrical grounding system.

Advantages

- Speed of installation: Fewer joints mean less leak risk and faster work.

- Flexibility: Ideal around machinery, tight spaces, or walls where rigid pipes are impractical.

- Corrosion-resistant: Stainless steel resists much better than black pipe.

Safety Considerations

- Must be properly bonded to the electrical system to avoid static charge issues or lightning damage.

- Training is essential as it offers no margin for error in bending or clamping.

Installation and Maintenance

Best Practices for Installation

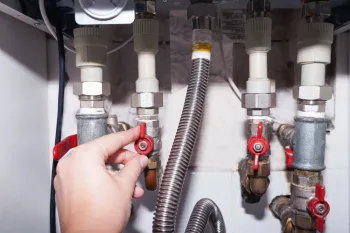

- Pipe Sizing and Layout: Use pressure/flow calculations to ensure appliances receive enough gas under all conditions.

- Proper Joint Techniques:

- Steel pipe requires torque wrenches or threading equipment and sealing tape.

- CSST bending machines and clamp plates ensure no pipe crushing.

- HDPE fusion joints must meet temperature and dwell specifications for reliable bonding.

- Anchoring and Supports:

- Pipe sag or vibration can stress joints, so you should use correct anchors, thermal supports or clamps.

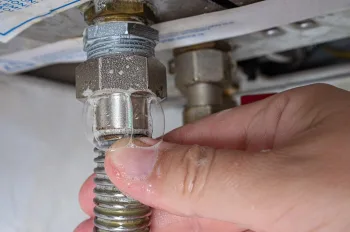

- Leak Testing:

- After installation, pressure-test the system at 1.5x nominal working pressure for 10–15 minutes to confirm seal integrity.

- Proper Exposure Protection:

- Exposed steel pipes need rust-resistant coatings; HDPE must be shielded from UV light.

Best Practices for Maintenance

- Annual inspections, including pressure checks and corrosion assessments.

- Regulator checks, verifying cut-in/cut-out pressures stabilise within appliance demands.

- Pipe cleaning or purging with clean gas to remove residues or obstructions.

- Damage tracking, particularly after construction work or environmental shifts affecting underground pipes.

Compliance and Standards

For safe and legal installations, gas pipes must meet these regulatory benchmarks:

- NFPA 54 (National Fuel Gas Code): Covers pipe sizing, materials, fittings, and regulator specifications.

- International Fuel Gas Code (IFGC): Used alongside NFPA guidance, often enforced through local authorities.

- ANSI B31.8: Focuses on gas transmission and distribution piping.

- Building adoption: Municipalities may add seismic, ventilation, bonding, or separation rules.

- Manufacturer directives: CSST tubing comes with tightening torques, bonding needs, and bending radius specifications that must be followed to maintain warranties.

Why Choose Our Gas Plumbing Services?

At Coastal Commercial Services, Inc., we specialize in comprehensive commercial gas plumbing solutions from material selection to expert installation, seamless pressure testing, and long-term maintenance planning.

Expert Material Selection

- Site-specific advice: We evaluate operating pressure, soil conditions, exposure, and appliance layout to recommend the optimal piping material, whether rugged steel, flexible CSST, or corrosion-resistant HDPE.

- Value-cost planning: We balance upfront material costs with long-term maintenance savings and code compliance to deliver the best ROI.

Professional Installation Services

- Certified gas-trained plumbers ensure each connection, be it steel, CSST, or PE, is installed per NFPA, IFGC, and local standards.

- Precision threading and torque control for steel connections using field-grade wrenches and penetrating oil to ensure gas-tight seals.

- CSST expertise, including proper bonding and strain-free bends installed with manufacturer-approved tools.

- HDPE fusion specialists ensure secure joints in underground or trenchless conditions.

Pressure Testing and Certification

- Every system undergoes 1.5x pressure decay testing using precision digital manometers.

- Our crews thoroughly check valves, regulators, and flame safety devices to confirm operational integrity.

- We provide compliance documentation with diagrams, serial numbers, and test data for permit or utility validation.

Maintenance and Inspection Programs

- Preventive maintenance packages include scheduled leak detection, pressure profiling, pipe corrosion surveys, regulator recalibration, and flame-testing across all installed piping.

- Rapid-response repair teams are ready 24/7 to address damaged sections—be it burst steel, cut CSST, or pinholes in HDPE, minimizing downtime and safety risk.

- Retrofit services, such as transitioning outdated copper or galvanized steel lines to modern CSST or coated steel for compliance and performance improvement.

Cost-Efficient Turnkey Solutions

- Design/build packages offer seamless pipe routing, regulator isolation station installation, and appliance connections in one streamlined plan.

- Value engineering evaluates material-life costs, balancing up-front pipe vs. lifecycle repair and inspection costs.

Our Skilled Gas Plumbers are Here to Help

At Coastal Commercial Services, Inc., we bring industry-leading competence in pipe selection, expert installation, pressure certification, and long-term maintenance planning. Our goal is to provide systems that not only meet national codes (NFPA, IFGC, B31.8) but deliver maximum efficiency, safety, and peace of mind for your operations.

Choose the right infrastructure from the start and a partner who supports it throughout its service life. To schedule your service, call us at (772) 248-0490 or contact us online.