Natural gas piping is the crucial backbone of any commercial or residential gas system, connecting the main gas feed to appliances such as furnaces, water heaters, stoves, and boilers. These pipes, made from various materials, are expected to uphold safety, efficiency, and reliability for decades.

Yet all materials deteriorate over time due to corrosion, pressure cycles, and environmental factors. Periodic inspections by a gas plumber can help identify any concerns with an aging pipe so that timely repairs and proper maintenance can be performed to extend its life.

The Average Lifespan of Gas Pipes

Different materials age differently under pressure, temperature swings, and environmental exposure. Here’s a comparative life expectancy breakdown:

Steel (Black and Galvanized)

- Black Steel Pipe: Reliable underground or indoor piping typically lasts 30–50 years, depending on environment, pressure, and coating. Above-ground installations may degrade faster due to humidity.

- Galvanized Steel: The zinc layer slows internal rusting, but over time, flaking can hinder flow and raise leak risk. Lifespan is reduced, generally 15–25 years in humid conditions.

Stainless Steel

High-quality 316 or 304 stainless steel pipe resists rust and corrosion far longer. With proper installation and bonding, it can last 50–80 years or longer in indoor and outdoor environments.

Copper

Aluminium-based Type K, L, or M copper tubing, used primarily for branch lines or propane, lasts 40–70 years. However, copper isn’t suitable for all natural gas applications and can have pressure limitations.

HDPE / PE-4710 (Plastic)

Approved for underground use, HDPE piping has a typical lifespan of 50–100 years. Its success depends on correct fusion joints and avoidance of rock abrasion.

CSST (Corrugated Stainless Steel Tubing)

Flexible CSST combined with proper bonding and grounding has a projected service life of 50 years or more, though protections against lightning must remain current.

Signs of Aging Gas Pipes

Timely inspection avoids costly failures. Watch for:

External Corrosion and Rust

Flaking paint, visible rust, or white powder deposits on steel pipes are signs of oxidation. If found on threaded or underground lines, immediate evaluation is needed.

Visible Deformation or Leaks

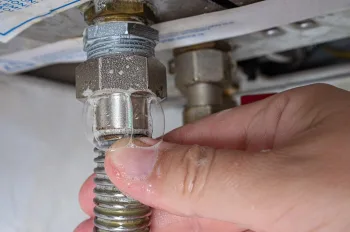

Condensation, gas smell, pilot light outage, or hissing near fittings indicate weakness. Even minor leaks accelerate into major failures under pressure.

Flushing and Flow Loss

Reduced pressure or slow appliance startup suggests internal buildup from rust (steel pipes) or blockages in copper tubing.

Discoloration or Cracking of Joints

Galvanized threads turning brown or black, softened solder in copper joints, or cracked fittings in plastic lines indicate failure risk.

Regular Inspection Indicators

Lines over 30 years old, recent renovations, changes in gas appliances, or high usage cycles should trigger renewed pipe assessment.

Gas Pipe Maintenance Tips

Proactive upkeep extends pipe life and efficiency:

Annual Inspection

Pressure-test lines at 1.5x normal operating pressure. Inspect visible pipe for corrosion, sag, or damage. Check accessible threading for seal integrity.

Environmental Protection

Apply rust-inhibiting coatings or wrapping especially in moist or corrosive environments. Avoid soil contact or chemical exposure by installing sleeves or barriers.

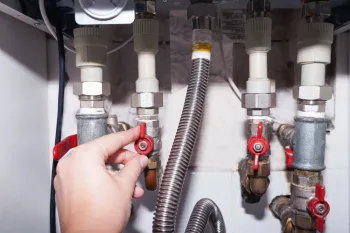

Regulator and Connector Integrity

Maintain regulators, valves, and CSST bonding. Check valves annually, clean regulator inlets, and inspect lightning protection.

Avoid Water Accumulation

Ensure gas piping remains dry. Drain condensation, ventilate trenches, and fix roof or pipe drips quickly.

Timely Upgrades

Swap out galvanized or older pipes when renovating or changing appliances. Consider modern materials like black steel or HDPE.

Record Keeping

Log pipe age, inspection dates, repairs, and material types. This assists with regulatory compliance and insurance processes.

Safety Considerations

Letting gas piping deteriorate can lead to:

- Gas Leaks & Explosions: A single compromised joint or corrosion site can release enough natural gas to cause a serious explosion.

- Carbon Monoxide Poisoning: Leaky joints or internal buildup can cause incomplete combustion, leading to CO poisoning.

- Business Downtime & Liability: Unexpected emergencies shut down operations, trigger evacuations, and risk civil and criminal liability.

- Fire Risk: A leak near an ignition source can cause rapid fire. Even tiny leaks increase the odds dramatically over time.

Do Not Delay Gas Pipe Repair or Maintenance

Natural gas line replacement becomes necessary when gas pipelines, especially steel pipelines buried underground, are prone to corrosion or show signs of aging. If not properly maintained, these gas pipes can develop leaks due to poor installation, ground movement, or simple wear over time. A hissing sound, rotten egg smell, or pressure drop are all warning signs that must be addressed immediately.

Delaying gas line repair or ignoring maintenance practices may result in costly repairs or serious safety hazards. Many factors, including soil conditions and pipe material, influence longevity, making early detection critical. Newer systems using high-density polyethylene (HDPE) and protective measures like cathodic protection can enhance durability and reduce risk.

Whether you are scheduling regular maintenance or planning a new gas line installation, always contact a qualified plumber immediately and coordinate with your gas company to ensure major pipelines are handled with precision.

How Our Gas Plumbing Specialists Can Help

At Coastal Commercial Services, we combine technical expertise with industry-best practices to manage every stage of the gas pipe lifecycle from inspection to replacement and long-term care.

Gas Pipe Inspection & Assessment

- Comprehensive site audits: We examine pipe materials, pressure points, age stats, and environmental risk to evaluate system health.

- 1.5x pressure decay tests: We pin down hidden leaks through mandated pressure testing across all accessible pipe branches.

- Material analysis: We identify pipe types, such as steel, galvanized, copper, HDPE, CSST, and their condition status.

- Engineered reports: We provide piping risk maps, locate vulnerabilities, and advise on sections requiring immediate or scheduled replacement.

Installation & Replacement Solutions

- Customized pipe selection: Depending on flow rates, installation type, corrosion risk, or seismic/thermal conditions, we specify steel, HDPE, or stainless steel lines.

- Certified installation crews: Our team installs black steel with precision threading, bonds CSST per NFPA 780 lightning protection, and safely lays HDPE in trenchless excavations with fusion machines.

- Compliance documentation: We deliver permit-ready diagrams, serial logs, scope summaries, and pressure specs validated by inspectors.

Repair & Maintenance Services

- Emergency repair response: With 24/7 availability, our crew can swap damaged sections within hours to restore fuel supply and structural integrity.

- Preventive maintenance plans: Scheduled inspections, pressure tests, bonding checks, regulator cleanings, and pipe coating service on recurring cycles.

- Retrofitting older lines: We partially remove and relight aged galvanized lines or integrate HDPE overlays for easier modernization.

- Comprehensive system audits: After renovation, our gas plumbing survey certifies compatibility of new appliances, regulator upgrades, and master shutoff improvements.

Choose Our Trusted Gas Plumbers for the Most Effective Results

Coastal Commercial Services offers a full-service solution from initial inspection and repair to replacement and ongoing maintenance. We safeguard every facet of installation, regulation, and structural integrity, so your gas infrastructure operates safely and efficiently for decades to come. To schedule your service, call us at (772) 248-0490 or contact us online.