Relocating a gas line is a complex, high-stakes plumbing task that demands precision, expertise, and adherence to safety regulations. Whether you’re updating your facility’s layout, installing new appliances, or undergoing a renovation, moving a gas line improperly can result in leaks, fire hazards, or regulatory violations. Contact a well-equipped commercial plumbing company for reliable gas line adjustment services.

Reasons to Move a Gas Line

- Appliance Reconfiguration: Reorienting stoves, water heaters, or boilers to improve workflow or meet updated design specifications.

- Facility Renovation: Walls, ceilings, or entire floor plans may shift positions during remodels, necessitating gas line realignment.

- Code Compliance & Upgrades: Older gas pipelines might need to be replaced with modern pipe types (e.g., black steel, CSST, or polyethylene) or rerouted to meet current building codes.

- Damage Avoidance: Preemptively avoiding future damage from adjacent renovations, electrical upgrades, or structural changes.

Common Scenarios and Challenges

- Underground vs. Above-Ground Lines: Underground pipes require trenching and careful excavation; above-ground pipes may be obstructed by framing, ducts, or ceiling elements.

- Clearance Considerations: Gas lines must meet specific clearance distances from electrical, water, HVAC, and structural systems.

- Material Matching: Ensuring gas line material (black steel, galvanized, or CSST) is properly matched to pressure requirements and appliance ratings.

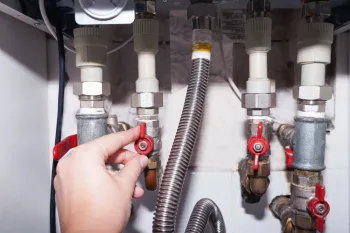

- Integration with Multiple Appliances: Central appliances like kitchen ranges or boilers require carefully balanced gas distribution, which adds routing complexity.

Preparation for Moving a Gas Line

Safety Precautions to Consider

- Gas Shut-Off and Isolation: Always shut off the main gas feed and depressurize the system before work begins.

- Ventilation: Work in well-ventilated areas; portable blowers may be necessary in confined spaces.

- Gas Detection Tools: Use both electronic gas detectors and combustible gas indicators to continuously monitor levels during work.

- Compliance Gear: Personal Protective Equipment (PPE) like spark-resistant tools, flame-resistant gloves, and gas-rated fittings is essential.

Steps to Assess the Existing Gas Line Setup

- Pressure Measurement: Determine current working and pressure test requirements (typically 1.5 to two times operating pressure, up to 12 inches WC for residential systems).

- Material & Age Verification: Confirm the pipe composition and inspect for corrosion, cracking, or previous weld failures.

- Layout Mapping: Create a blueprint of current pipes, including branch lines, valves, fittings, and appliances. This serves as a reference for rerouting.

- Utility Coordination: Notify local gas companies and request marking services to avoid damaging subsurface lines or utilities.

Tools and Materials Required for Moving a Gas Line

- Pipe Sections & Fittings: Black steel, galvanized, or corrugated stainless steel tubing (CSST) compatible with local code and appliances

- Threading or Flaring Tools: For seamless end connections, pipe threading sets for steel or flaring tools for CSST

- Joint Sealing Materials: Gas-rated pipe dope, PTFE tape, or approved sealants as specified by product and code requirements

- Pressure-Test Equipment: An accurate manometer and gauge that measures up to the required test pressures

- Wrenches, Cutters, and Supports: Including tubing cutters, pipe wrenches, high-quality supports, clips, and labeling tags

Step-by-Step Guide on How to Properly Disconnect and Relocate a Gas Line

- Depressurize the System: Turn off the gas supply and bleed residual gas into a well-ventilated outdoor area.

- Cap and Secure Existing Lines: Temporarily cap the line using approved fittings and tape, clearly marking them as “inactive.”

- Route and Plan the New Path: Sketch the new routing, prioritizing clearance, avoiding sharp bends, and locating shutoff valves appropriately.

- Cut and Reconnect: For steel pipe, measure, cut with a pipe cutter, re-thread ends, and apply sealant before installing fittings. For CSST, use specialized cutters and install approved compression fittings per manufacturer guidelines.

- Secure Piping: Use suitable hangers, clips, and supports to avoid strain, vibration, or pipe sagging.

- Pressure Test the Final Assembly: Conduct a pressure test at 1.5× operating pressure or as required; hold for a minimum of 10 to 15 minutes and monitor for pressure loss.

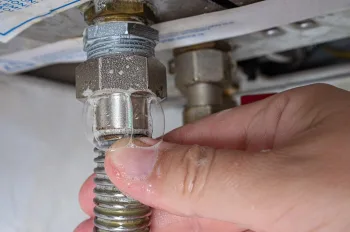

- Leak Detection: Apply soapy solution or use an electronic detector along joints and fittings; all visible bubbles or detection alarms require immediate tightening or rework.

- System Restoration: Gradually restore gas supply, relight pilot lights, and reconfigure appliance regulators. Record final pressures.

- Documentation and Compliance: Provide inspection authorities with piping diagrams, pressure test logs, and material certificates. Label pipes according to code (e.g., “Gas Line—Black Steel—Natural Gas”).

Follow-Up Tasks After the Gas Line Relocation

Once your plumber has completed the gas line relocation with verification successful, waiting on final approval from the utility company may involve coordinating access to the gas meter. A discussion starter with the utility’s inspector usually begins by pulling up the ray ID or job reference number, which ensures your house is correctly identified for security and compliance checks.

If the inspector is slow to respond, it may prevent you from proceeding with construction or putting your appliances back online. Occasionally, completing this process is blocked by the need to pull wire or reroute connections. Working with a licensed plumber helps manage these delays efficiently while keeping costs and disruption to a minimum.

Why Choose Our Professional Services for Gas Line Movement?

Here’s why clients trust Coastal Commercial Services for complex tasks such as moving a gas line:

- Skilled Gas and Plumbing Team: Our technicians are licensed gas plumbers and trained in national and state code compliance, ensuring safe, dependable installations.

- Full-End-to-End Service: From layout planning to final labeling and certification, we manage all phases, eliminating coordination issues and ensuring traceability.

- Cutting-Edge Tools and Equipment: We use industry-leading equipment from gas detectors to precision pressure gauges to deliver precision execution and safety.

- Safety-First Methodology: We follow strict lockout/tagout protocols, implement on-the-job air monitoring, and ensure zero-emission systems before resuming any services.

- Quality Materials: We source commercial-grade piping (black steel, CSST) with full traceable certifications and secure code-compliant fittings.

- Pressure Testing and Documentation: Our pressure testing always exceeds minimum requirements, and our detailed reports ensure easy review for local inspectors.

- Minimized Operational Downtime: We use modular piping assemblies and coordinate work during off-peak hours to reduce facility disruptions.

- Code and Compliance Assurance: We remain current with local gas regulations, whether OSHA, NFPA 54 (USA), or CEA (Canada), so your project passes inspection smoothly.

- Emergency Support and Aftercare: Our human support extends post-installation, offering immediate emergency response, ongoing maintenance, and inspections to uphold safety and reliability.

Call Us for Safe and Reliable Gas Line Adjustment Services

At Coastal Commercial Services, our experienced gas-plumbing team handles everything from initial design and pressure testing to final inspections and safety documentation. Choose the leader for safe, code-compliant, and efficient gas line relocation. To schedule your service, call us at (772) 248-0490 or contact us online.